| Sign In | Join Free | My burrillandco.com |

|

| Sign In | Join Free | My burrillandco.com |

|

| Ask Lasest Price | |

| Brand Name : | Xinkunda |

| Model Number : | Customizable according to requirements |

| Certification : | ISO9001,ISO14001,ISO45001 |

| Price : | 1535 USD/metric ton (current price) |

| Payment Terms : | T/T |

| Supply Ability : | 2000 tons/month |

| Delivery Time : | 2-7 days |

The PPS Board is an advanced engineering material designed to meet the rigorous demands of various industrial applications. Known for its exceptional chemical resistance, this Chemical Resistant PPS Board stands out as a reliable solution for environments where durability and stability are paramount. Manufactured from high-quality polyphenylene sulfide (PPS), this board combines superior mechanical properties with excellent thermal and chemical resistance, making it an ideal choice for a wide range of applications.

One of the key attributes of the Engineering PPS Plastic Board is its outstanding flammability rating of UL94 V-0. This rating signifies that the material is highly flame-retardant, self-extinguishing within 10 seconds after being ignited, and does not produce flaming drips. This essential safety feature makes the PPS Board suitable for use in electrical components where fire safety standards are critical. Engineers and designers can trust this material to provide enhanced safety without compromising performance.

The PPS Board is available in customized sizes, allowing for flexibility in design and manufacturing processes. Whether you need small precision parts or large sheets for structural applications, the Engineering PPS Plastic Board can be tailored to meet your specific requirements. Its natural color, a subtle beige or light brown, offers a neutral aesthetic that can easily blend with other materials or coatings without the need for additional finishing.

Mechanical strength is another hallmark of this Chemical Resistant PPS Board. With a flexural strength ranging from 120 to 150 MPa, the board exhibits excellent resistance to bending and deformation under load. This property is particularly valuable in applications involving dynamic stresses or heavy mechanical loads. The Board’s robust mechanical performance ensures longevity and reliability, reducing the need for frequent replacements and maintenance.

The versatility of the Engineering PPS Plastic Board extends to its wide range of applications. In the electrical industry, it is commonly used for manufacturing components such as insulators, connectors, and housings that require high electrical insulation and flame resistance. Its chemical resistance also makes it suitable for automotive parts that are exposed to oils, fuels, and other aggressive substances, ensuring durability and consistent performance over time.

Beyond electrical and automotive uses, the PPS Board is highly regarded in industrial machinery manufacturing. Components made from this material can withstand harsh operating conditions, including exposure to chemicals, heat, and mechanical wear. This makes the board an excellent choice for machine parts, gears, and structural elements that demand high strength and chemical stability.

In summary, the Chemical Resistant PPS Board is a premium Engineering PPS Plastic Board that offers an ideal balance of flammability resistance, mechanical strength, and chemical durability. Its customizable size and natural beige/light brown color provide flexibility and aesthetic appeal, while its UL94 V-0 rating ensures safety in critical applications. Whether you are developing electrical components, automotive parts, or industrial machinery, this PPS Board delivers reliable performance and long-lasting quality.

Choosing the Engineering PPS Plastic Board means investing in a material that supports innovation and safety in demanding environments. Its unique combination of properties makes it a trusted choice among engineers and manufacturers looking for a high-performance solution that does not compromise on safety or durability.

| Color | Natural (Beige/Light Brown) |

| Surface Finish | Smooth |

| Thickness | 3-30mm |

| Applications | Electrical Components, Automotive Parts, Industrial Machinery |

| Flammability Rating | UL94 V-0 |

| Material | Polyphenylene Sulfide (PPS) |

| Water Absorption | < 0.1% |

| Size | Customized |

| Flexural Strength | 120 - 150 MPa |

| Melting Point | 280 - 285 °C |

The Polyphenylene Sulfide Board is a highly versatile material renowned for its exceptional mechanical and chemical properties, making it ideal for a wide range of applications. This High Performance PPS Board, characterized by a density of 1.35 - 1.38 g/cm³ and an impressively low water absorption rate of less than 0.1%, offers outstanding dimensional stability and durability even in the most demanding environments. Its natural beige to light brown color further enhances its appeal for use in various industrial contexts.

One of the primary application occasions for the Polyphenylene Sulfide Board is in the manufacturing of electrical components. Thanks to its excellent electrical insulation properties and resistance to heat and chemicals, the High Performance PPS Board is extensively used in the production of connectors, insulators, and housings for electronic devices. Its stability under thermal stress ensures reliable performance in high-temperature environments, making it a preferred choice for electrical applications that require long-term durability and safety.

In the automotive industry, the Polyphenylene Sulfide Board plays a crucial role in the fabrication of automotive parts. The material’s inherent resistance to chemicals, moisture, and high temperatures allows it to be used for components such as fuel system parts, under-the-hood components, and various structural elements. The High Performance PPS Board’s low water absorption ensures that parts maintain their integrity and performance even when exposed to harsh conditions, contributing to the overall reliability and longevity of vehicles.

Industrial machinery is another key area where the Polyphenylene Sulfide Board finds extensive application. Its robustness, combined with excellent wear resistance and dimensional stability, makes it suitable for gears, bearings, and other mechanical parts subjected to continuous stress and friction. The natural color of the High Performance PPS Board also allows for easy visual inspection and quality control during manufacturing processes.

Overall, the Polyphenylene Sulfide Board’s unique combination of low density, minimal water absorption, and high-performance material properties make it an indispensable solution for applications requiring superior strength, heat resistance, and chemical stability. Whether in electrical components, automotive parts, or industrial machinery, this High Performance PPS Board consistently delivers excellence and reliability across diverse industrial scenarios.

Our PPS Composite Material Board offers exceptional product customization services to meet your specific requirements. With a density range of 1.35 - 1.38 G/cm³, our Polyphenylene Sulfide Board is designed for high performance in various applications including electrical components, automotive parts, and industrial machinery.

The High Performance PPS Board can be manufactured with thicknesses ranging from 3 to 30mm, providing flexibility for different design needs. We utilize advanced manufacturing methods such as injection molding, extrusion, and machining to ensure precision and quality in every product.

Additionally, our PPS Board boasts a heat deflection temperature between 260 - 280 °C, making it suitable for demanding environments where thermal stability is critical. Trust our customization services to deliver reliable and durable PPS Composite Material Boards tailored to your industry specifications.

Product Technical Support and Services for the PPS Board are designed to ensure optimal performance and customer satisfaction. Our support team is dedicated to providing timely assistance for installation, configuration, troubleshooting, and maintenance of the PPS Board.

We offer comprehensive documentation, including user manuals, technical specifications, and FAQs to help users understand and utilize the product effectively. Additionally, software updates and firmware upgrades are made available to enhance functionality and security.

For technical issues beyond the scope of documentation, our expert support staff is available to provide remote diagnostics and problem resolution. We also offer repair services and replacement parts to maintain the longevity of your PPS Board.

Training sessions and webinars are periodically conducted to help users stay informed about best practices and new features. Custom integration support is available for clients requiring specialized configurations or compatibility with other systems.

Our commitment is to deliver reliable and efficient support to maximize the value and performance of your PPS Board investment.

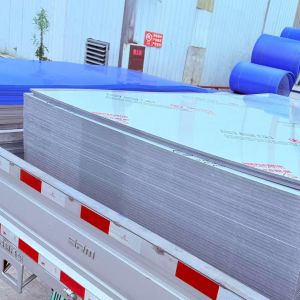

Our PPS Board product is carefully packaged to ensure maximum protection during transit. Each board is wrapped in protective film and placed between sturdy cardboard layers to prevent damage. The packaged boards are then securely stacked on pallets and shrink-wrapped to maintain stability.

For shipping, we offer multiple options including air freight, sea freight, and express courier services. All shipments are tracked with detailed documentation provided to the customer. We ensure timely delivery with reliable logistics partners to meet your schedule and requirements.

Q: What material is the PPS Board made of?

A: The PPS Board is made from high-quality Polyphenylene Sulfide (PPS), known for its excellent chemical resistance and thermal stability.

Q: What are the typical applications of the PPS Board?

A: PPS Boards are commonly used in electrical insulation, mechanical parts, automotive components, and chemical processing equipment due to their durability and resistance to harsh environments.

Q: What temperature range can the PPS Board withstand?

A: PPS Boards can typically withstand continuous operating temperatures up to 260°C (500°F), making them suitable for high-temperature applications.

Q: Is the PPS Board resistant to chemicals?

A: Yes, PPS Boards have excellent chemical resistance to acids, bases, solvents, and hydrocarbons, making them ideal for use in aggressive chemical environments.

Q: What are the mechanical properties of the PPS Board?

A: The PPS Board offers high mechanical strength, good dimensional stability, and excellent wear resistance, ensuring long-lasting performance in demanding applications.

|